Innovative LED illumination technology offers many benefits for microscopy, but CoolLED’S Core Technology team has also been busy working on a new concept to advance machine vision applications.

Why use LED illumination for machine vision?

As any microscopist with a CoolLED Illumination System knows, our LED technology offers homogenous, powerful and highly controllable illumination across the spectrum – and these properties are ideal for hyperspectral imaging.

This modern approach to machine vision can sort, grade, assess or analyse products (be it food, pharmaceutical products or money) with unprecedented detail. However, this has traditionally relied on halogen illumination which is problematic and not suitable for automation. As LED technology has reached a stage of acceptable power & homogeneity, this is set to become the illumination of choice and open the way to fast, efficient hyperspectral imaging.

There are also cost and environmental benefits to replacing inefficient and heat-producing halogen lamps. As halogen illumination in the consumer sector is being phased out by the UK government, it is only a matter of time before commercial applications follow suit – from microscopy to hyperspectral imaging.

A future promise or today’s reality?

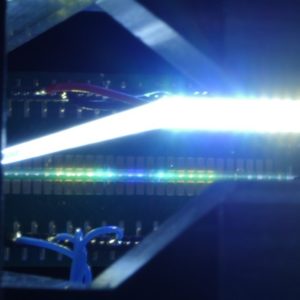

Once thorough in-house testing of our prototype line illuminator delivered impressive performance data, we felt ready to take the plunge and put our technology to the test at VISION 2021 last month.

It was a tough crowd to please, but from overall response we did just that – mainly by letting the data speak for itself. As the line illuminator was wired up to the spectrometer, visitors to our booth could monitor the performance and homogeneity across the spectrum in real time. From several conversations, we are now confident in our ability to offer high-performance LED line illumination for hyperspectral imaging compared to both halogen lamps and alternative LED solutions currently available.

The next step is optimising the features such as line width, length and working distance to progress from prototype to finished product, so watch this space for updates.

Find out more about LED illumination for machine vision and get in touch.

You can also find out what it’s like working with CoolLED!